Novel biobased furanic-aliphatic polyesters that are biodegradable and have tunable properties

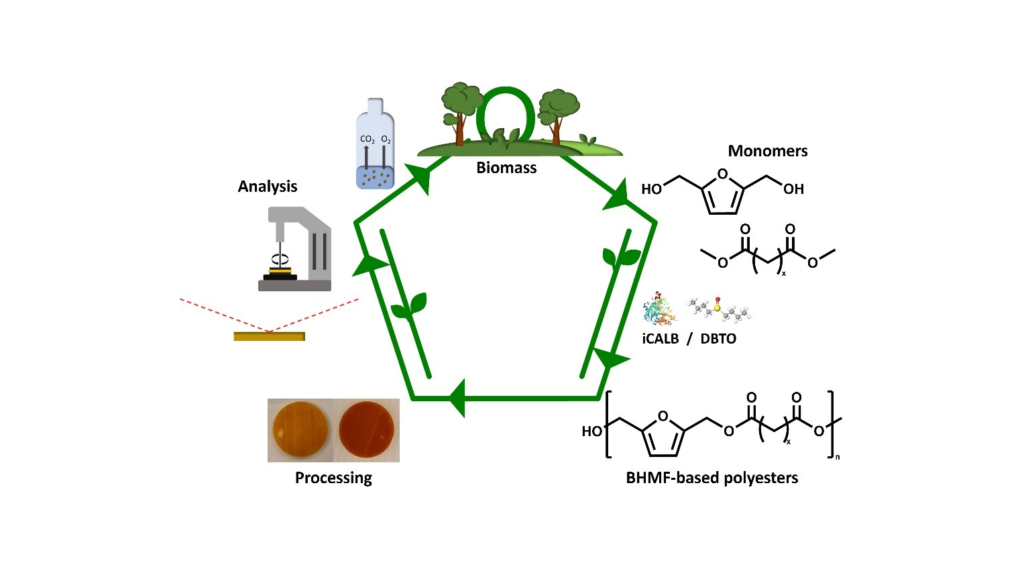

The negative consequences of fossil raw materials are becoming more visible today, with examples including extreme weather and plastic waste pollution in the environment. Commodity plastics such as polyethylene terephthalate (PET), polypropylene (PP) and polyethylene (PE) are indispensable in society, but they also contribute to these problems. Biobased polymers, on the other hand, have a lower carbon footprint while still possessing comparable properties to traditional commodity plastics. 2,5-Furandicarboxylic acid (FDCA) is a monomer for the production of poly(ethylene 2,5-furandicarboxylate) (PEF), a prominent biobased alternative for PET. 2,5-Bis(hydroxymethylfuran) (BHMF), a structurally similar monomer to FDCA, is a promising but understudied sugar-derived building block. BHMF can be derived from sugars via a straightforward and facile 5-hydroxymethylfurfural (HMF) reduction, which produces high yields.

BHMF-based Polyesters

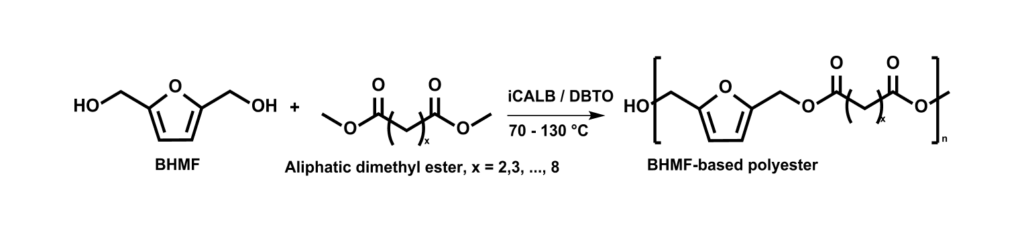

However, the synthesis of biobased polyesters based on BHMF is challenging due to the limited stability of this interesting furanic monomer. Although, a series of BHMF-based polyesters were produced via a green and efficient bulk polymerization process by using either an enzyme (iCALB) or a commercially available catalyst (DBTO). The number of methylene units in the aliphatic comonomer varied from 2 to 8, and the influence of this on the thermal behavior and stability of the polymers was investigated. An oscillatory shear rheology investigation demonstrated significant differences between the melt behavior of the BHMF-based polyesters. A clear inversely proportional correlation between the low-frequency complex viscosity and the number of methylene units in the aliphatic segment was observed. Finally, a biodegradability test revealed that the synthesized BHMF-based polyesters had a biodegradable character over time, wherein different biodegradation rates were observed related to the length of the aliphatic segments in the repeating units.

Conclusion

This work emphasized that renewable BHMF-based polyesters can be produced via a solvent-free and sustainable process, and that their biodegradability and thermal and rheological properties can be tailored by varying the number of methylene groups in the aliphatic unit. In conclusion, these polymers are very interesting materials to play a role in the circular plastic economy. This work was recently published in Green Chemistry, more information can be obtained here: https://pubs.rsc.org/en/Content/ArticleLanding/2024/GC/D4GC01512F

Author: Corniek Post

Links

https://pubs.rsc.org/en/Content/ArticleLanding/2024/GC/D4GC01512F

https://www.rug.nl/research/zernike/macromolecular-chemistry-and-new-polymeric-materials/group-loos/

Keywords

BHMF, Biobased, Enzymatic polymerization, Polyesters, Rheology, Biodegradation