Metabolic engineering of microbial strains for production of long-chain diols and diacids

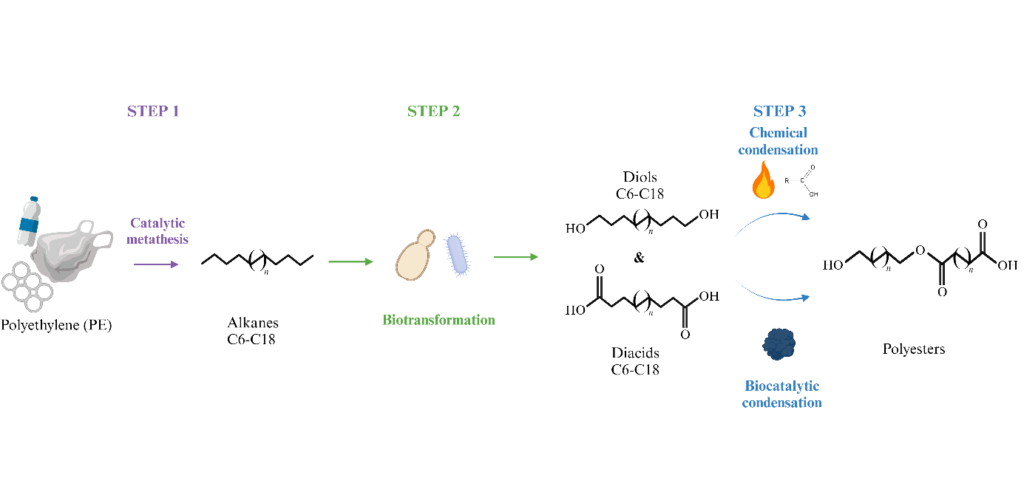

ACTPAC is a highly innovative and promising project which aims at the bio-chemical conversion of polyethylene (PE) (petroleum-based plastic) into bio-based polyesters (bio-based plastics). Shortly, PE waste streams are transformed into a well-defined range of C6-C18 alkanes (STEP 1) which are amenable for further conversion towards diols and diacids monomers (STEP 2) that are finally used for polyester production (STEP 3) (Figure 1). All these steps will also be scaled-up.

The University of Münster is working on STEP 2: improving different microorganisms to convert long-chain alkanes (C14-C18) to long-chain diols and diacids (C14-C18). But let’s start from the beginning:

Can microbes naturally metabolise alkanes? The answer is yes, some microbes were found to happily grow in petroleum reservoirs [1]. By that, they can use alkanes as a substrate for growth and, consequently, they already possess interesting enzymes and enzymatic pathways to convert alkanes to other kinds of molecules that can be exploited for biotechnological based products.

To convert long-chain alkanes to long-chain diols and diacids, we do not want the microbes to grow on alkanes, we want them to transform alkanes directly to the desired monomers of interest. Hence, a biotransformation by the use of so-called resting cells is the approach we will apply.

What does biotransformation by resting cells mean? In this microbial based approach, two substrates are used: a primary substrate (substrate for growth) and a secondary one (substrate which will be converted) [2], [3]. Cells grow on the primary substrate, whereas the secondary substrate (in our case alkanes) does not support cell growth, but it is transformed to other compounds of interest, in our case diols and diacids.

To successfully achieve this approach, microbes must be engineered to avoid the consumption of alkanes for biomass formation. Furthermore, the microbial strains require optimised metabolic pathways to produce diols and diacids with high efficiency and specificity. For this part of the ACTPAC project, metabolic engineering and omics techniques are combinatorically used to reach this goal [4]. Furthermore, process optimization is applied to evaluate the best conditions for the strains to strive and reduce operation costs. Once efficient and robust strains are developed, the University of Münster in collaboration with Biolynx will enable the scale-up of this bioprocess.

Stay-tuned to see how this fantastic project develops!

Author: Giulia Ravagnan and Jochen Schmid

References

[1] S. N. Singh, B. Kumari, and S. Mishra, “Microbial Degradation of Alkanes,” in Microbial Degradation of Xenobiotics, 2011, pp. 439–469. doi: 10.1007/978-3-642-23789-8_17.

[2] Y. Nor Suhaila et al., “Biotransformation using resting cells of Rhodococcus UKMP-5M for phenol degradation,” Biocatal Agric Biotechnol, vol. 21, Sep. 2019, doi: 10.1016/j.bcab.2019.101309.

[3] I. Funk, V. Sieber, and J. Schmid, “Effects of glucose concentration on 1,18-cis-octadec-9-enedioic acid biotransformation efficiency and lipid body formation in Candida tropicalis,” Sci Rep, vol. 7, no. 1, Dec. 2017, doi: 10.1038/s41598-017-14173-7.

[4] Y. S. Ko et al., “Tools and strategies of systems metabolic engineering for the development of microbial cell factories for chemical production,” Chem Soc Rev, vol. 49, no. 14, pp. 4615–4636, Jul. 2020, doi: 10.1039/d0cs00155d.

Links

https://www.uni-muenster.de/Biologie.IMMB/

Keywords

Bio-based plastics, bioprocess, microbes, metabolic engineering