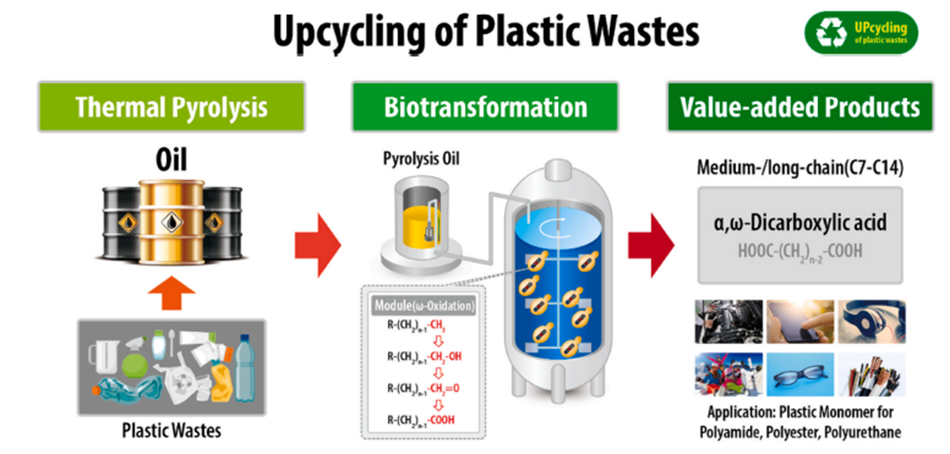

Engineered yeast converts waste plastic pyrolysis oil into valuable α,ω-diacids with high efficiency

The accumulation of plastic waste is a significant environmental issue, with traditional disposal methods posing health and ecological risks. The study by Yeo et al., published in Journal of Cleaner Production in April 2024 offers a novel approach to repurpose mixed plastic waste into valuable α,ω-diacids using chemo-biological processes. They successfully extracted pyrolysis oil from household plastic waste and utilized a genetically engineered Candida tropicalis strain to convert it into α,ω-diacids of varying chain lengths.

α,ω-Diacids are essential monomers for creating polymers like polyester, polyamide, and polyurethane, with the carbon chain length in these building blocks significantly influencing polymer properties. Medium-chain α,ω-diacids (C8 to C12) offer superior flexibility, chemical resistance, low moisture absorption, and stress crack resistance, making them ideal for use in the automotive and electronics industries. However, their production currently relies on complex, multi-step chemical processes that are inefficient, generate hazardous by-products, and depend on unsustainable petroleum-based feedstocks. This method leads to environmental challenges, including pollution and global warming.

Sustainability and cost-effectiveness

This innovative strategy not only provides a technical solution but also promotes a shift towards a circular economy, reducing our dependence on fossil fuels. The method’s effectiveness is evident in its ability to convert various plastic wastes with efficiencies comparable to or better than traditional petrochemical processes. Its scalability and cost-effectiveness have been demonstrated through successful industrial adoption.

Bio engineering and optimisation

This study also lays the groundwork for developing microbial strains optimized for producing specific α,ω-diacid chain lengths, further enhancing the value of plastic-derived pyrolysis oils. Future research will focus on refining microbial strains through genetic and metabolic engineering to improve specificity and efficiency in producing targeted α,ω-diacids. Additionally, optimizing fermentation conditions and downstream processing will be crucial for increasing yield and purity. There is also potential to integrate novel degradation methods to expand the range of plastic waste types that can be processed.

Ultimately, the goal is to create a closed-loop system where plastic waste is repurposed, contributing to a sustainable cycle of material management.

The approach to upcycling mixed plastic waste into valuable α,ω-difunctional chemicals represents a significant advance in sustainable waste management and material recovery. They utilize a combination of chemical and bio-based techniques to transform low-value plastic waste into high-value chemical precursors. By employing the yeast C. tropicalis, they can efficiently convert plastic waste into valuable medium-chain α,ω-diacids.

This article was based on the study by Yeo et al., published in Journal of Cleaner Production in April 2024 [1].

Author: Sara Hubo

References

[1] I.-S. Yeo et al., ‘Integrating chemical and biological technologies in upcycling plastic waste to medium-chain α,ω-Diacid’, Journal of Cleaner Production, vol. 451, p. 141890, Apr. 2024, doi: 10.1016/j.jclepro.2024.141890

Links

https://www.sciencedirect.com/science/article/pii/S0959652624013386?via%3Dihub

https://www.elsevier.com/locate/jclepro

Keywords

biotransformation, bio engineering, Candida tropicalis, mixed plastic waste, diacids, upcycling